When it comes to fabric testing, one of the most crucial factors to consider is the bursting strength of the material. Bursting strength refers to the ability of fabric to resist pressure before rupturing or breaking. Choosing the right Burst Tester or Bursting Strength Testing Machine is essential for ensuring that the fabric meets the required standards for quality and durability. Whether you are a textile manufacturer, quality control specialist, or fabric supplier, understanding how to select the proper testing equipment is key to ensuring accurate and reliable results.

1. Understand the Importance of Bursting Strength Testing

The Bursting Strength Tester is used to evaluate how much internal pressure a fabric can withstand before breaking. This test is vital for fabrics used in products like airbags, tents, or raincoats, where durability is paramount. Bursting strength also plays a significant role in the production of materials used in medical textiles, packaging, and protective wear. By choosing the right tester, you can prevent failures and ensure that the fabric is suitable for its intended purpose.

2. Types of Bursting Strength Testers

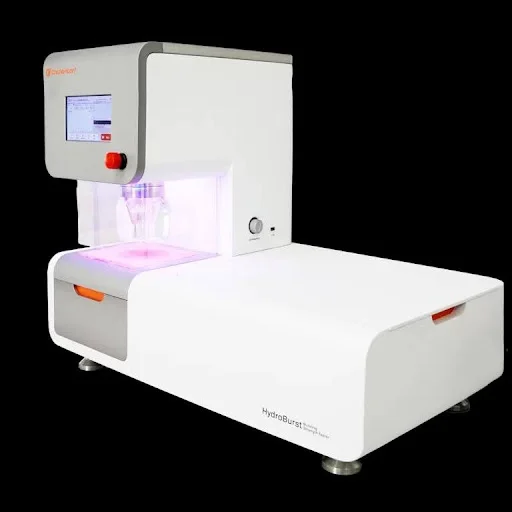

There are several types of Bursting Strength Testing Machines available in the market, and understanding the differences between them is essential to choosing the right one for your needs.

- Pneumatic Bursting Tester: This machine applies air pressure to the fabric sample, increasing the pressure until the fabric bursts. It is ideal for fabrics that are flexible or stretchable. Pneumatic testers provide precise and reproducible results, making them suitable for high-precision applications.

- Hydraulic Bursting Tester: Similar to pneumatic testers, hydraulic machines use water to apply pressure. This method is often used for thicker fabrics or materials that require more pressure to burst. Hydraulic testers are also beneficial for simulating real-world conditions where fabric might face higher levels of pressure.

- Servo-Controlled Bursting Strength Tester: This modern version uses a servo motor to apply constant pressure, offering high levels of accuracy. These testers are suitable for fabrics with varying thickness or composition and provide faster testing with automated results.

3. Key Features to Look For

When choosing a Bursting Strength Testing Machine, it is important to focus on several key features to ensure you’re getting the right equipment for your needs.

- Pressure Range: The machine should be able to measure a broad range of bursting strengths, from low-pressure materials to high-strength fabrics. Choose a tester with adjustable pressure settings to cater to different fabric types.

- Accuracy and Repeatability: Precision is crucial in fabric testing. Look for a tester that provides consistent, reproducible results across multiple tests. Machines with high accuracy ensure that your test results are reliable and useful.

- User-Friendly Interface: A machine with an intuitive interface makes the testing process more efficient. Easy-to-use software with the ability to record and analyze test results will streamline your workflow.

- Durability and Maintenance: Opt for a Burst Tester that is built to last and easy to maintain. A durable machine will save you time and money on repairs and replacements in the long term.

4. The Importance of Calibration and Compliance

To ensure the accuracy of your Bursting Strength Testing Machine, regular calibration is essential. Make sure the machine complies with international standards such as ASTM, ISO, or JIS, as compliance guarantees the reliability and credibility of your test results. Calibration ensures that the machine operates within the specified parameters, providing consistent and dependable results.

5. Consider Your Specific Testing Needs

Finally, consider the specific materials and applications you are working with. If you are testing lightweight fabrics, a pneumatic tester may be sufficient. For thicker or more robust materials, a hydraulic machine could be a better fit. Take into account the volume of testing required, the fabric types you deal with, and your overall budget. Some Burst Tester models offer additional features, such as automated reporting or integrated testing programs, which can be beneficial depending on your operational needs.

Conclusion

Choosing the right Bursting Strength Testing Machine is crucial for ensuring the durability and performance of your fabrics. By understanding the various types of testers available, their features, and the importance of regular calibration, you can make an informed decision that suits your specific testing requirements. Investing in the right Bursting Strength Tester will not only help maintain high-quality standards but also ensure that your products meet the necessary safety and performance standards.

For more information on textile testing methods/standards

or Textile Testing Machine-TSETEX textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com sales@tes.hk